High quality decking screws

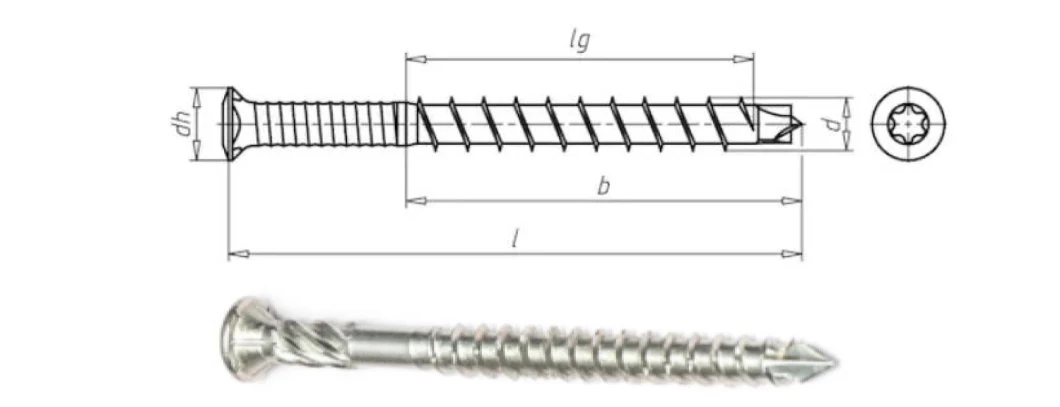

| Product details | |

| Product Name | Decking screw |

| Length | 10mm-350mm |

| Diamater | M2.5--M20 according to customer requirements |

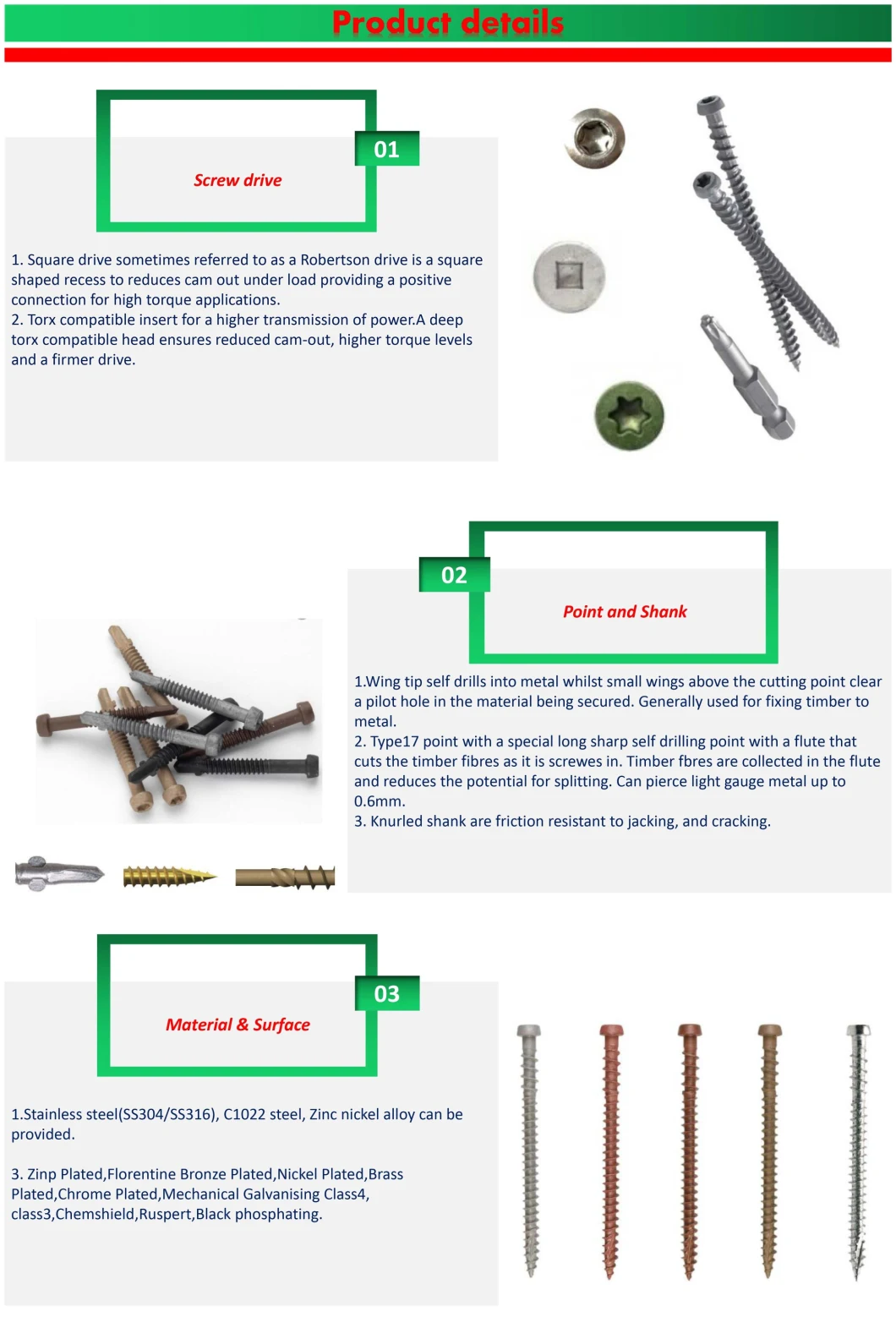

| Available material | Stainless steel(SS304/SS316), C1022 steel, Zinc nickel alloy |

| Surface treatment | Zinp Plated,Florentine Bronze Plated,Nickel Plated,Brass Plated,Chrome Plated,Mechanical Galvanising Class4, class3,Chemshield,Ruspert,Black phosphating. |

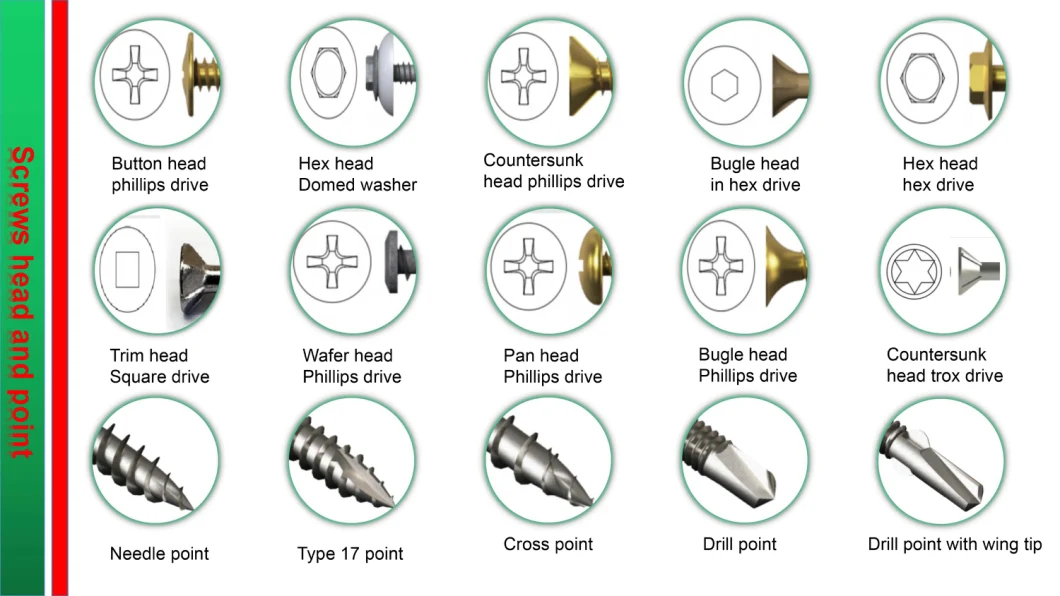

| Point | Type 17 /needle point /drill point /wing tip |

| Head | Pan, countersunk, Button, Trim head... |

| Thread | Coarse thread, Fine thread, Full thread, Non-full thread. The sawtooth pattern, Serrated thread. |

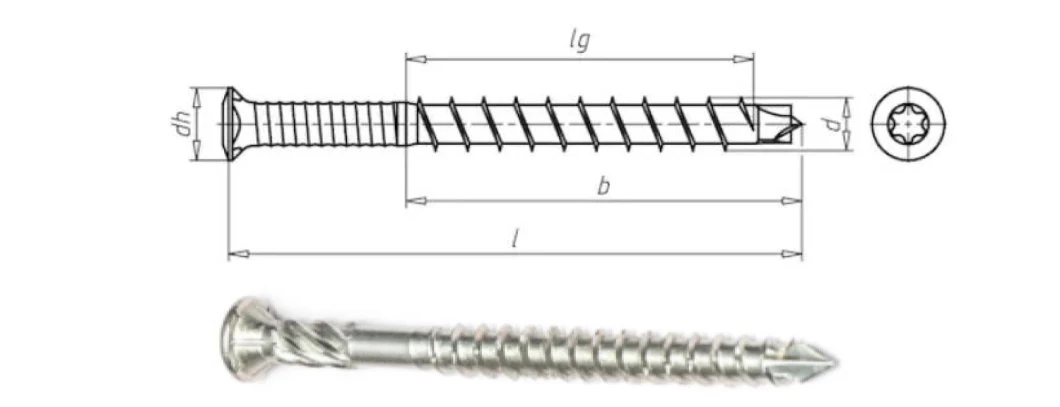

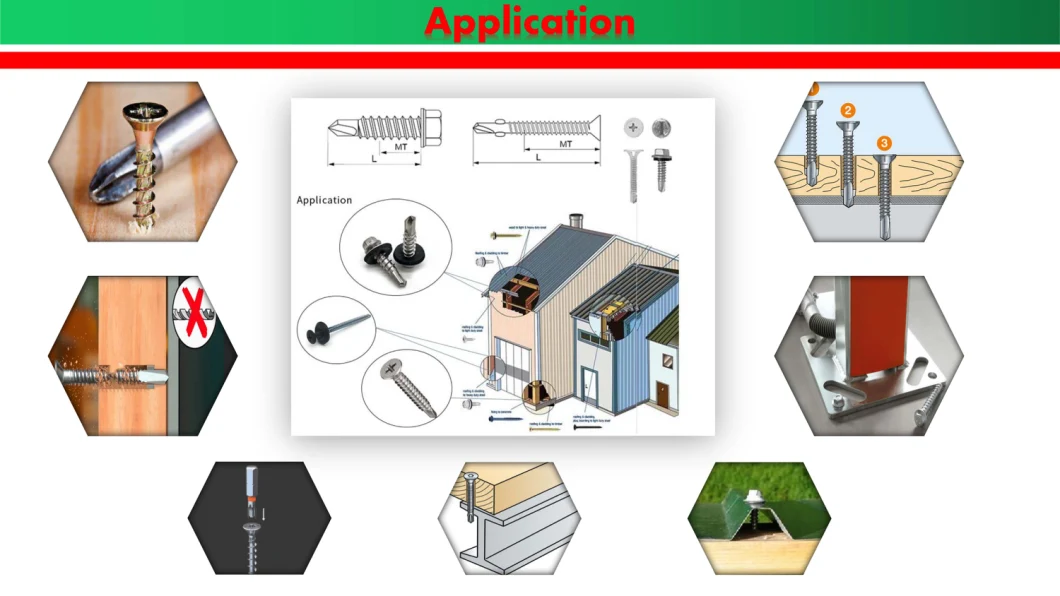

Features:

Features in our decking screw range include high corrosion resistance and slash tips to remove the need for pre-drilling which reduces splitting. Our deck screws are available in a choice of head types and colour to help you achieve the perfect finish every time. Available in a variety of lengths and pack sizes for ease on larger projects.

- Easy to screw in

- High tensile strength

- Avoid cracking and splitting

- Deep and sharp thread for cutting through wood cleanly

- Excellent quality and high temperature treatment for resistance to snapping

- Different choices of dimensions and surfaces

- Construction authorities approved

- Long service life

OEM & ODM can be accepted.

1. Professional technical team can provide technical drawings according to the actual use of customers. In addition to regular head, drive, and tip type, special shapes can be designed.

2. Screws and packaging can be customized according to customer requirements. Strong design team for you to build your own brand.

3. All kinds of special and mixed packaging can be accepted.

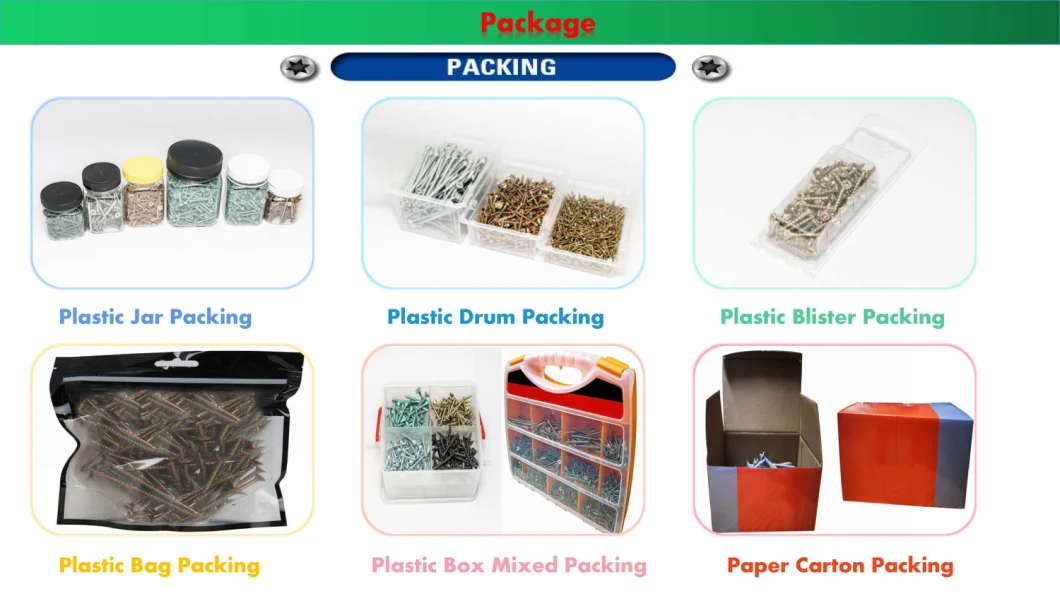

Different package can be customized!

1. Plastic jar packing: Be favored by supermarkets and brand customers. High quality anti - theft plastic bottle. The number of screws per bottle can be adjusted according to customer requirements. With the customer's logo and any information that needs to be displayed can be put on the bottle in the form of stickers.

2. Plastic drum packing: Essential packaging for brand customers. The extra large capacity can accommodate more quantities or extra long specifications.

3. Plastic blister packing: Lightweight packaging can perfectly hang on the shelves of supermarket customers.

4. Plastic bag packing: Simple and portable packaging, There is a seal on the plastic bag to ensure the tightness of the bag.

5. Plastic box mixed packing: Mixed packaging can fully meet the needs of customers. Different box types can be designed. When customers need different specifications screws at the same time. This will be the best choice.

6. Paper carton packing: 5-layer corrugated high-quality carton can fully ensure firmness. Different colors and designs can be customized.

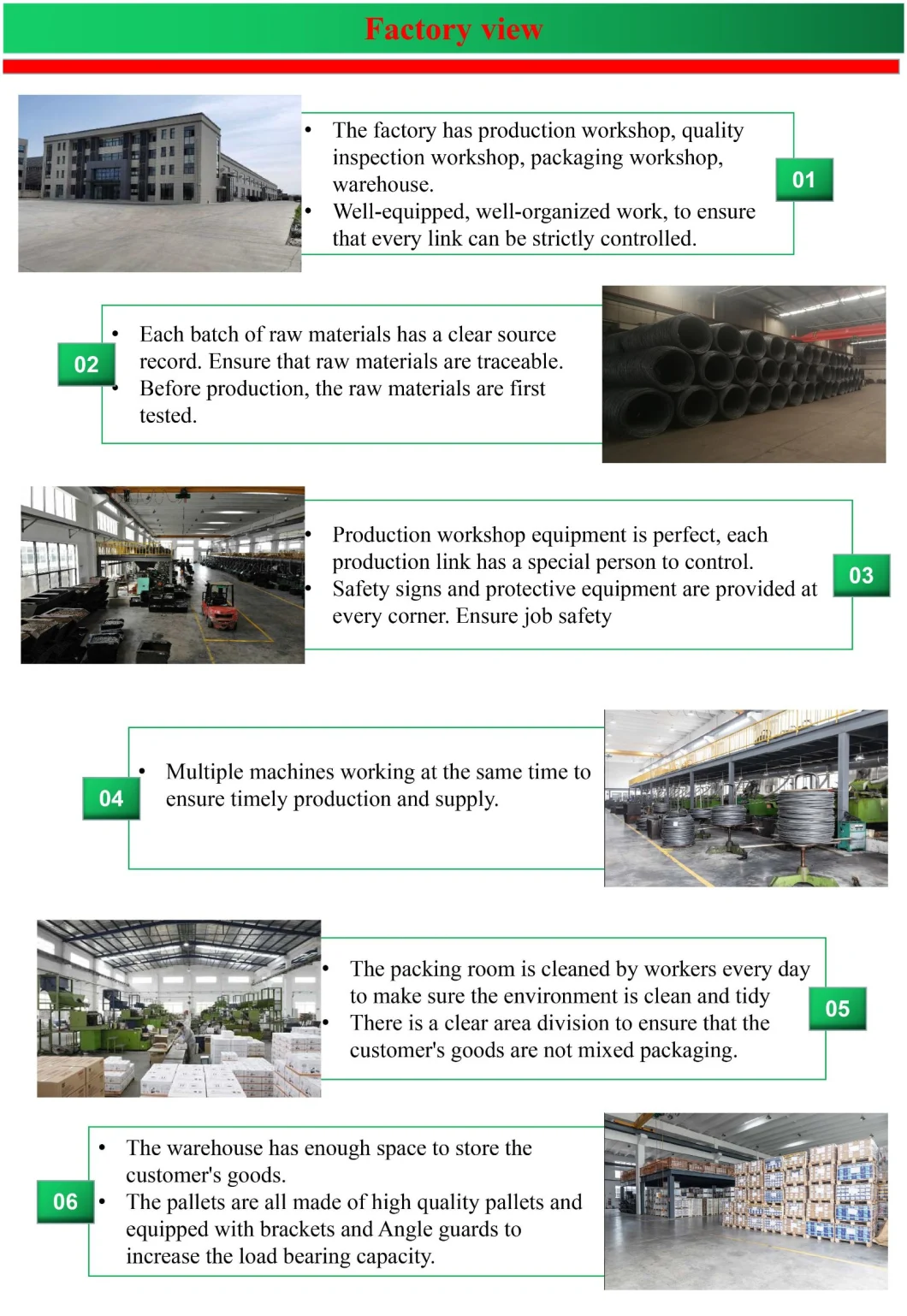

FQC:There is a set of strict control procedures from production to quality inspection to packaging.

1. Choose high quality C1022 or stainless steel wire according to customer needs.

2. From cold heading, thread rolling to heat treatment, passivation, all are strictly controlled.

3. Data measurement is to ensure that the finished product fully meets the requirements of technical drawings. Before production, the complete technical drawing can be provided to customer.

4. The drill test generally adopts 1-6mm steel plate to check if the product will fail due to thread breakage during assembly. Make sure that the screws can be used normally.

5. Use the created artificial simulated salt spray environmental conditions to assess the corrosion resistance of the product to ensure that the screws can meet the standards.

6. Check that the product is rotated or twisted in the assembly due to insufficient torque. Screen out any unqualified products.

7. During packaging, quality inspectors will randomly check the packaging quantity. The sticker will be checked before pallet.

Welcome to contact us !