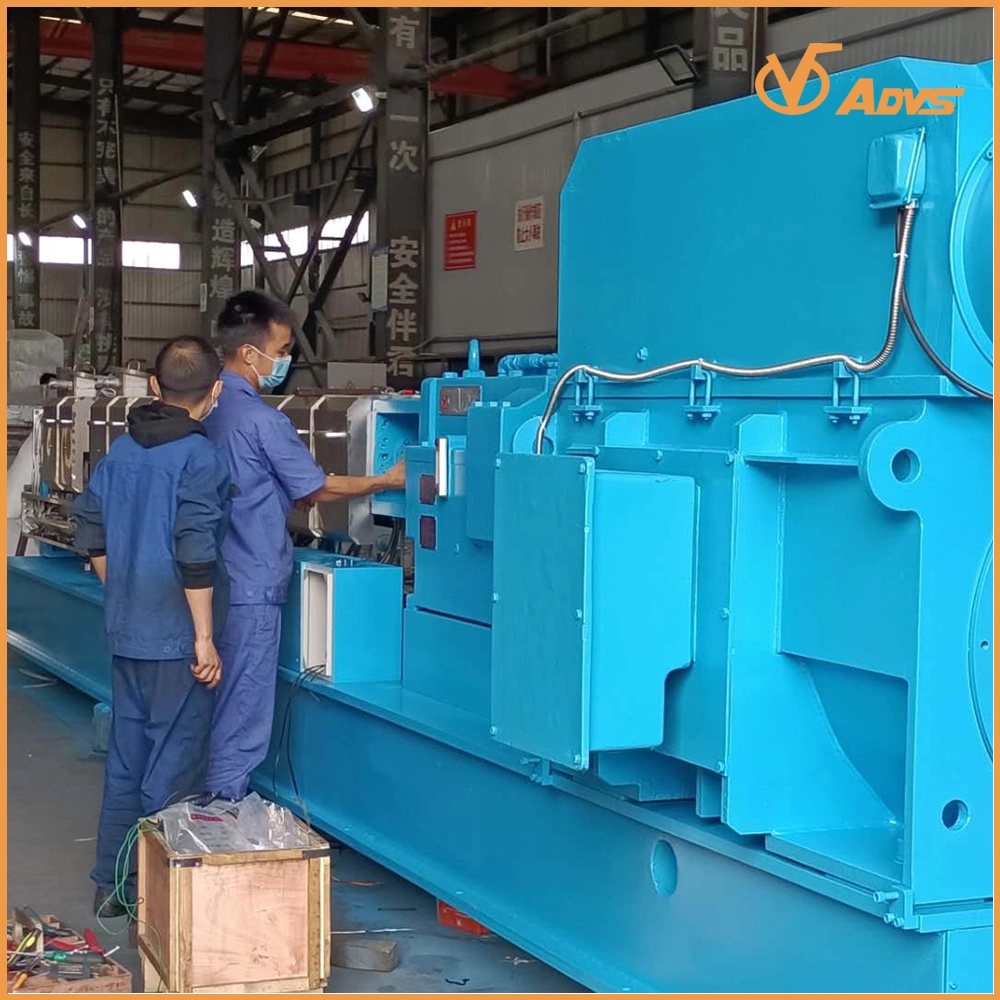

Twin screw Extruder for melt blow PP for surgical masks

Product Description:

Sichuan Advance technology Co.,Ltd is dedicate to dewvelop, design, and manufacture co-rotation, counter- rotation parallel twin screw extruder production line. we integrate and upgrade these experiences to create our transmission concept and form our core technology" bilateral gear symmetrical driving system". The technology enables our extruders have the advantages of "High torque, high efficiency, low energy-consumption, high price/performance ratio,long service life." We keep pace with the first class extruder manufactures in the world.

Exhibition:

Configuration feartures of HPL series extruder

1. gearbox: bilatral symmetry gear drive system; design service life more than 72000hrs, average torque coefficient=10.4, brand of bearing are Sweden SKF and Germany INA;

2.Torque limiter:torque limiter imported from Germany;

3.Barrel: integrated wear-resistant alloy steel liner; Channel of barrel is annular jet type, not easy to belocked;

4.Scew shaft: material of screw element is W6Cr5Mo4V2; Material of shaft is high imported from Finland.

5. Heating medium: heating rod imported from Germany;

6. Machine frame: high rigidity whole steel plate welding;

Electrical system: PLC and instrument control for your choice; control cabinet and power cabinet are seperate, strong and weak electrical are isolated installed.

Technical datas of PHL62 series high standard extruder

| TYPE/DATAS | PHL51 |

| screw diameter | 51mm |

| L/D | 60:1 |

| motor power | 160KW |

| max speed | 600 |

| High torque | 12 |

| Oouput range | 300kg-450kg |

Typical application

Reinfoce modification:PP,PA,PBT, ABS,, PC, POM, PPS, PET+Carbon fiber, glass fiber

Filled modification: PE, PP, EVA+CaCo3,talcum powder,titianium dioxide, carbon black and other inoranic filler;

Masterbatch:color masterbatch,flame retardant masterbatch,carbon black masterbatch,degradable masterbatch;

Plastic alloy:PC+ ABS, PA+ABS, PA+PE, PBT+PET,etc.

Special Engineering Plastic: PEEK, PEI, PPS,PPSU, PA6T,PA9T,LCP,etc.

High compouding dispersion extrusion:nano material, powder coating and fiber grade masterbatch;

Reaction extrusion: polyreaction andpolycondension;

| contact person | Chelsea Tian |