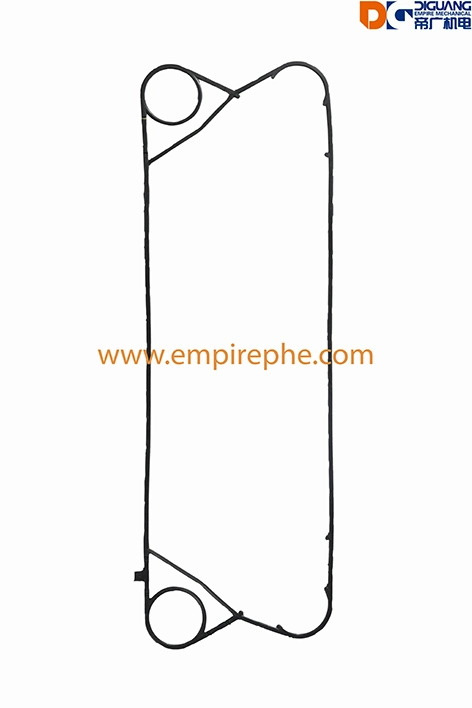

TS6M Clip On Flow Gasket For Plate Heat Exchanger

Specifications1.Plate heat exchanger, plate gasket, professional manufacture

1. Wide application

2. ISO9001 and ISO14001

3. Clip-on, Sounder lock, Glued, Button lock

4. High efficiency with low cost

5, Spanish service

6, Short delivery in time

7,Easy to install and maintain

8,We Look forward to get your inquiry and start our cooperation !

9. Reply massage at the first time

Shanghai Empire Mechanical engineering is engaged in producing and supplying PHE plates, PHE, and PHE gaskets. Apart from VT series replacement plate, we also provide the replacement plate of NT series and free-flow series for PHE.

In addition, we can also offer plate expansion, cleaning, as well as product design and calculating services.

Component Material

Heat exchange plate: SS304, SS316, Alloy C276, ASMO254 titanium, nickel, Hastelloy alloy

Gasket seal: NBR, H-NBR, EPDM,Viton, FKM, food pad, fluorine rubber, silicon rubber

Plate Thickness:0.5mm, 0.6mm, 0.8mm, 1.0mm

Plate type: Double-Wall, Free-Flow, Semi-Welded

Frame: Carbon steel, stainless steel, coated stainless steel

Clamping bolt: Galvanized carbon steel, stainless steel

Interface: Rubber, carbon steel, stainless steel

Guide bar: Galvanized carbon steel, stainless steel

Typical Application: Automotivo, Caustic Soda, Chemical, Food, HAVC, Marine and Shipboard, Metal Working, Petroleum, Power, Pulp and Paper, Stell, Textile etc.

The plate heat exchanger possesses a series of superior properties to other heat transfer equipment, such as excellent flexibility, high heat thermal efficiency, low cost and easy maintenance. Our product with corrugated plates is engineered to achieve turbulence across the entire heat exchanging area, achieving optimal heat transfer coefficients with the minimal pressure loss. That is to say, the smaller the heat transferring area and the device are, the more benefits customers can get due to less space, lessened flow rate and smaller pump.

There are a certain number of plates corrugated in different designs and arranged among the pressure frames, enlarging the total surface area of the plate heat exchanger. In the frame, the plated can be moved and mounted on the carrying bar that is located at the top and bottom of the frame. Seen from the sideway aspect, paired plates arranged oppositely form a honeycomb pattern.

Both the fixed plate and the pressure plate are supported by columns and connected by the gaskets, which get the materials sealed from sideway or through holes on the plates. Meanwhile, the gaskets are arranged crossly so as to prevent the fluids in the passages from mixing.